Installation & Operation Instructions for

In-dash MR2 Wideband AFR Gauge

Contents of package:

1 x wideband AFR gauge

1 x switch with mounting ring

2 x machine screws (to mount gauge)

4 x washers/spacers

Notes before installation:

1) Always ground yourself using a static control wrist strap when working on the gauge cluster during installation of the EMSPowered gauge. This will prevent the possibility of damage from static shock. Static shock is especially dangerous in cold/dry climate.

2) When handling the gauge be careful not to scratch the lense. The lense is durable but will easily scratch if handled improperly.

3) Have some wire ready for your installation.

Tools/items needed:

* Philips screwdriver

* Flathead screwdriver

* Drill

* 1/4″ drillbit

* 3/8″ drillbit

* Enough wire to connect the guage and switch

* Electric tape and/or wire insulation

Installation:

1) Remove the screws holding the plastic trim underneath the steering column. After you remove the screws the piece should snap off with a little bit of pressure. See the following pictures to show the locations of these screws:

2) When you snap the plastic cover off, you will need to remove the socket connected to your foglight switch (if you have one installed):

3) Now remove your shift knob by unscrewing it (counterclockwise). After you remove the shift knob remove the leather shift boot by pulling it upwards until it snaps out of place:

4) Remove your ashtray by pulling it upwards. Now remove the two screws behind the ashtray:

5) Now you can remove the plastic trim surrounging the A/C vents, radio, and A/C controls by pulling gently until it snaps out of place on all corners. You will need to remove the sockets connecting to your cigarette lighter adapter and also your hazard light button:

6) Remove the screw directly to the left of the ignition/key tumbler:

7) Remove the plastic trim piece surrounding the steering column and the far left A/C vent by gently pulling until it snaps out of place. You will need to remove the socket connecting to the dimmer knob:

8) Remove the 3 remaiining screws holding the gauge cluster in place:

9) Remove the plastic trim piece at the top of the gauge cluster by pulling gently downward until it snaps out of place:

10) This is the most difficult part of the installation. You will need to tilt the gauge cluster forward on one side, reach behind it and remove the cables connected to it in the back. This is easier on 93+ cars with an electrical speedo. On 90-92 cars this is more difficult because of the mechanical speedo which has a cable connected to the back of the gauge cluster which tends to be difficult to remove.

After you remove the cables from the back of the gauge cluster, tilt your steering wheel all the way down and manuver the gauge cluster assembly out. At this point you are ready to get started with the installation of the new gauge.

11) Take a break, get a soda, and pat yourself on the back. You are past the most difficult part.

12) Find a clean area that you can work on the gauge cluster. A large table works really well, to allow space to spread your items out without losing anything.

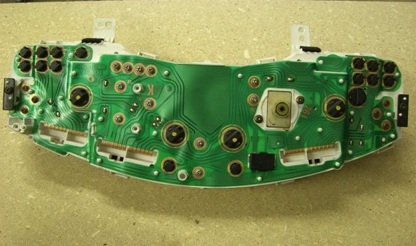

13) Start by removing the front black bezel from the gauge cluster. You do this by undoing the tabs/clips holdling the black bezel to the white housing. You may need a flathead screw driver to pry the tabs loose. After you remove the black bezel your gauge cluster will look like this:

14) Remove the two screws holding the stock Toyota boost gauge (or voltage gauge) in place on the back of the gauge cluster:

15) After removing the screws, pull up gently on the stock Toyota boost gauge and remove it from the cluster:

16) Using a 1/4″ drill bit, drill a hole in the spot shown in the picture below:

17) Remove your EMSPowered AFR gauge from the protective plastic bag. Carefully put each of the wires through the hole you drilled in the previous step. After you get all of the wires through mount the gauge to the cluster using the two screws provided. After you mount the gauge, clip the black bezel back onto the gauge cluster to make sure the gauge sits flush against the bezel. If there is a small gap, you will need to use the provided washers to space the gauge upwards to sit flush with the black bezel. This is due to variation in the gauge clusters. Your Mounted gauge should look like the following before assembling the gauge cluster back together:

18) Now you will need to decide where you want to mount the programming switch. Most people will mount it next to the dimmer knob. Using a 3/8″ drill bit drill a hole in the location you’d like to mount the switch. Then push the switch assembly through the hole and mount it using the mounting ring provided with the switch. Make sure not to overtighten the ring. In this picture the switch is mounted to the center trim piece next to the ashtray:

20) Now you will need to connect the wires. Use the following as a guidline:

Wires from the gauge:

* Red –> +12V switched power source

* Black –> connect to ground

* White –> connect to universal 5V output signal wire from your wideband controller – If you are using an Innovate LC-1 the white wire from the gauge should be connected to the brown wire from the Innovate LC-1

* Green –> connect to headlights (or parking lights) switch for dimming/nighttime feature to function (optional)

* Orange –> connect to one of the wires coming from the switch (either wire will work)

* Connect the other unused wire from the switch to ground.

Note: If you use a chassis ground make sure you chean the surface of residue/paint so that you get a solid connection.

21) After you have finished the wiring turn the key to the on position to make sure that the gauge is functioning. Also, make sure that the switch is functioning. After you have confirmed this re-install the gauge cluster along with all of the trim pieces that you previously removed. Make sure to reconnect all of the cables connecting to the back of the gauge cluster.

Congratulations, you’ve installed the all new EMSPowered AFR gauge!

Operation:

There are 2 settings “sections” – one for configuring the data / linear equation to be displayed, and another for general settings. The data setup should be performed first as follows: with the ignition key off, press the button on the gauge and hold it down. While down, turn the ignition key to the ON position (do not start the vehicle) so that the gauge powers up. It will go directly into the first mode of the data configuration section. Here you will set the endpoints for the linear data-set to be displayed, the range, and the software-filtering level.

Data Configuration:

In this data-configuration section, press and hold the button for a few seconds to change the mode. Press and release quickly (tap the button) to change the setting in any mode. Some of this may take time, so plan everything first and you’ll save yourself some hassles – you should only have to do this once. Data configuration modes are as follows:

| MODE | DISPLAY | SETTINGS |

| Set Range | 0.00 | Tap button to select between the range – either 0.00 to 9.99, 0.0 to 99.99 or 0 to 999 |

| Set value of 0V | Ya | Set the display value represented by a value of 0V |

| Set value of 5V | Yb | Set the display value represented by a value of 5V |

| Set software filter level | IIr | Sets the filter level from 1 (soft/slow) to 15 (hard/fast), or off |

Filtering:

On any signal line within an automobile, there will be electrical noise present. The firmware within the gauge samples (electronically reads) the input data hundreds of times per second, and averages a few of these at a time to cancel out the effects of noise. However, the noise level may vary depending on the specific vehicle and installation. Due to it’s high sensitivity (for maximum accuracy), and its high sample rate, some of this noise will be shown on the gauge as “flickering” or “toggling” numbers (rapid oscillation between two or more values, usually on the lowestvalue digits). But depending on the data being measured, you may not need high update rates and may wish to use more filtering. An example of this is measuring the liquid level in a bucket that is moving, where you don’t want the gauge to respond to every change in the sensor value as the liquid sloshes around, but rather you’re interested in the average liquid level. The gauge has very powerful IIR software filtering internally, which essentially “decays” the change of the current input value from the last input value, so that the gauge takes longer to “settle” to the new value. The IIR filter level is adjustable from 1 to 15 of off, where the higher the number, the less filtering and hence quicker updates. Switching the filter off provides the data change rates. For gauges such as voltmeters, tachometers and boost gauges, less filtering (higher IIR values) are more desirable; for air-fuel ratio gauges, mid-level filtering works well, and for temperature gauges, speedometers or liquid level, more filtering (lower IIR values) generally work better.

Input Voltage:

If you are using the Innovate LC-1, make sure to use output 2 (brown wire) from the LC-1 as the signal wire. Output 2 on the Innovate LC-1 by default is set to equal 7.35:1AFR at 0V and is set to equal 22.39:1AFR at 5V. If you want more accuracy you can reduce this to a narrower range in the Innovate software (and translate those settings onto the EMSPowered AFR gauge as well. For example, if you expect to be between 9:1 and 18:1 AFR’s, then you can change this setting in the Innovate software to equal 9:1AFR at 0V and equal 18:1 AFR at 5V, then set this same value on the EMSPowered AFR gauge. This is an extremely useful tool to get the most accurate readout possible on your gauge.

General Settings:

Once the data points have been set, you can continue around back to the first data-configuration mode, or you can switch the ignition key off/on to get to the normal operating mode where you can access the remaining general modes/settings. After you’ve cycled the ignition key and the gauge is back in normal mode, Press and hold the button for a few seconds to change the mode. Press and release quickly (tap the button) to change the setting in any mode. Modes are as follows:

| MODE | DISPLAY | SETTINGS |

| Normal | Current output value | |

| Brightness Regular | Br.9 | Daytime brightness setting |

| Brightness Parkinglights On | BP.1 | Nighttime brightness setting (activated by the green dimmer wire) |

Recent Comments